|

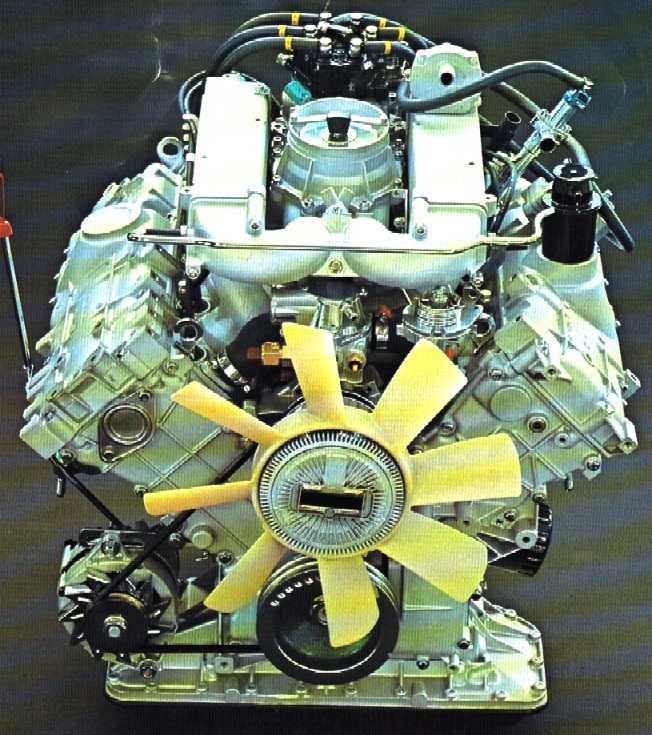

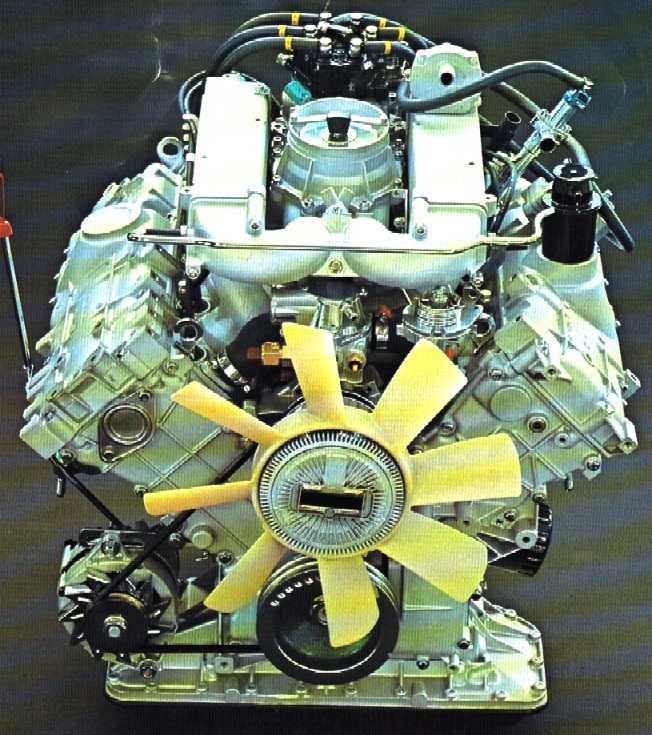

The Borzoi joystick

prototype was originally

fitted with an injected Peugeot V6 engine of 2.8 litres, giving

approximately 200hp (as seen below). The engine in the Borzoi was dry sumped

with straight through sport exhausts, with ramjet force feeding to the air

inlet. An

oil cooler was added and the viscous fan shown here, replaced with a pair of

electric fans mated to an alloy finned cooling radiator - which

unfortunately, did not cool well due to the engines higher state of tune.

The replacement radiator system to cure this problem was fabricated but

never fitted. The mechanical fuel pump was also replaced with an electric

fuel pump. It was on the cards to fit the turbo-charger as fitted to the

Renault Alpine GTA - but again, events overtook the designer. One can only

imagine the performance had this taken place. Club racers (Ultima)

equipped with this engine were obtaining upwards of 300bhp.

After

this car, the inventor migrated to electric engines - as seen in some of

the pictures at the foot of this page.

The

Borzoi's engine - PRV V6 2.8 liter alloy block with cast liners

PRV

HISTORY

The PRV engine is

a petrol unit that was developed jointly by Peugeot, Renault and Volvo Cars

(hence PRV) – sold from 1974 to 1998. It was gradually replaced after 1994 by another joint PSA-Renault design, known as the ES engine at PSA and the L engine at Renault.

In 1966, Peugeot and Renault entered a cooperative agreement to manufacture common components. The first joint subsidiary, La Française de Mécanique (also called Compagnie Française de Mécanique or simply FM) was launched in 1969. The FM factory was built in Douvrin near Lens in northern France. The PRV engines are sometimes referred to as "Douvrin" engines, though that name is more commonly applied to a family of straight-4s produced at the same time.

In 1971, Volvo joined Peugeot and Renault in the creation of the PRV company, a public limited company (plc) in which each of the three manufacturers owned an equal portion. The company originally planned to build V8 engines, although these were later scrapped in favor of a smaller and more fuel-efficient V6.

The PRV engine could be seen as a V8 with two missing cylinders, having a 90 degree angle between cylinder banks, rather than the customary 60, but with crankpins being 120 degrees apart. The Maserati V6 of the Citroën SM followed a remarkably similar pattern of development.

The 1973 energy crisis, and taxes levied against engine displacement greater than 2.8 litres made large V8 engines somewhat undesirable, and expanded the market for smaller displacement engines.

Additionally, Renault needed a V6 engine to fit in its new model, the Renault 30. Renault's internal designation for the PRV was Z-Type.

Machinery for assembling the engines arrived at Douvrin in early June 1973, and buildings for producing the engines were finished in January 1974. The first PRV engines were officially introduced on 3 October 1974 in the Volvo 264. Adoption was swift, and the PRV V6 had been sold in at least five different models by the end of 1975.

In 1984, the first commercially available turbocharged PRV V6 was sold in the Renault 25 V6 Turbo. This was the first to be even-fire with split crankpins, and was the first of the second generation, and indeed EFI engine of any sort. Turbocharged versions went on to be used in the Renault Alpine GTA V6 Turbo (essentially the same engine as the 25 Turbo at 2,458 cubic centimetres (150.0 cu in)), Renault Alpine A610, and Renault Safrane Bi-turbo – both with 2,963 cubic centimetres (180.8 cu in) low compression. Naturally aspirated 2,963 cubic centimetres (180.8 cu in) and 2,975 cubic centimetres (181.5 cu in) versions of both low and high compresson 3 litre engines appeared in a number of Peugeot, Citroen and Renault cars until 1997.

While Renault were working forced induction into the PRV, Peugeot and Citroen developed their own 24 valve engines as an option in the 605 and XM respectively. The compression remained the same as the Renault 12v, but the pistons differed, as did some of the timing gear, and the heads were re-engineered to allow easier maintenance (the camshaft being fitted from the opposite end for example). This engine was however extremely expensive, and suffered cam wear problems. This was due to the exhaust valves sharing a single lobe, while each inlet valve had its own lobe. This was at least partially solved by the use of ceramic followers as one of a succession of recalls.

Meanwhile, French supercar manufacturer Venturi had been developing their own versions of the PRV. The most powerful versions they built were in the Atlantique 300 at 207 kilowatts (281 PS; 278 bhp) from a single turbocharged 3.0 L 12v, and they successfully raced at the 24 Hours of Le Mans with the 600LM with a twin turbocharged 24v 3.0 litre, pushing out over 450 kilowatts (610 PS; 600 bhp) in race spec, and the road-going spin-off, the 400GT managed 300 kilowatts (408 PS; 402 bhp). This used the low compression bottom end common to the Renault turbo engines, coupled to 24 valve cylinder heads with bespoke rockers and tappets.

Peugeot too allowed a small group of engineers to create a team for endurance racing, and after a few years the team grew to be called WM Peugeot. The ultimate version of the car used a low compression 3.0 litre bottom end coupled to bespoke twin-cam heads. It is the only DOHC PRV. This car still holds the top speed record at 24 Hours of Le Mans set in 1988. By taping over the engine cooling intakes to improve aerodynamics, the team managed to push the car to 407 kilometres per hour (253 mph) on the 5 kilometres (3.1 mi) straight before the engine was destroyed.

Volvo began to withdraw from the PRV consortium in the late 1980s, shifting its powerplant reliance onto in-house inline engines. Peugeot, Renault and Citroën continued using the PRV until 1997.

After producing 970,315 units, production of the PRV V6 was stopped on 15 June 1998.

ENGINEERING - Ignition timing

The original engineering work done on the V8 engine can still be seen in the resulting V6 engine: its cylinder banks are arranged at 90°, instead of the much more common 60°. V8 engines nearly universally feature 90° configurations, because this allows for a natural firing order. V6 engines, on the other hand, are generally arranged at 60° (again because of timing), but can be built as 90° engines, with either staggered timing or split crankshaft journals. 90° V6 engines are shorter and wider than 60° engines, allowing lower engine bay hood/bonnet profiles.

First-generation PRV engines (1974–1985) featured uneven ignition timing. Second generation PRV engines (introduced in 1984 in the Renault 25 Turbo) featured split crankshaft journals and even ignition timing all electronically

controlled. Other similar design examples are the odd-fire and even-fire Buick V6 and the Maserati V6 seen in the Citroën SM.

DE

LOREAN

John DeLorean had originally envisioned that the car would produce somewhere around 200 horsepower (150 kW), but eventually settled on a 150 horsepower (110 kW) output for the engine. However, United States emissions regulations required that parts such as catalytic converters be added to the vehicle before it could be sold there. This caused a 20 horsepower (15 kW) reduction to the vehicle's power output, a loss which seriously impeded the DMC-12's performance. When this combined with the suspension system changes, the US version was regarded as disappointing. DeLorean's comparison literature noted that the DMC-12 could achieve 0–60 mph (0–96 km/h) in 8.8 s, respectable for the early 1980s, but Road & Track magazine clocked the car at 10.5 s. It is possible that the factory performance numbers were achieved using a European-spec car with the 150 horsepower (110 kW) engine.

VARIATIONS

Z7U-702: Used in the Renault 25 V6 Turbo

Z7X-711: Used in the Eagle Premier/Dodge Monaco

Z7X-715: Used in the Eagle Premier/Dodge Monaco

ZM112: Carbureted version used in the Peugeot 504

ZMJ140: Fuel-injected version used in the Peugeot 504

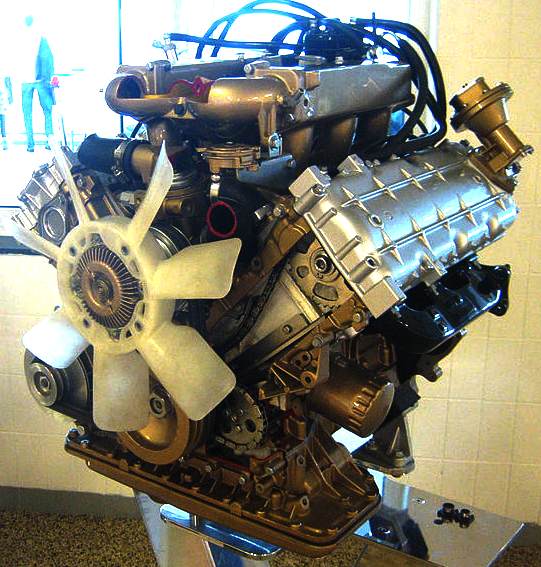

ZMJ-159: Fuel-injected version used in the DeLorean DMC-12

ZN3J: Fuel-injected version used in the US-spec Peugeot 505

ZNJK: Fuel-injected version used in the Peugeot 604

SPECIFICATIONS

power (DIN): 100 kilowatts (136 PS; 134 bhp) at 92 r/s (136 hp at 5,500 rpm) [3]

power (SAE): 97 kilowatts (132 PS; 130 bhp) at 92 r/s (130 hp at 5,500 rpm)

torque (DIN): 215 newton metres (159 lbf·ft) at 48 r/s

torque (SAE): 208 newton metres (153 lbf·ft) at 48 r/s (153 lb·ft at 2,750 rpm)

compression ratio: 8.8:1

cylinder bore: 91 millimetres (3.58 in)

piston stroke: 73 millimetres (2.87 in)

displacement: 2,849 cubic centimetres (173.9 cu in)

firing order: 1-6-3-5-2-4

mass (weight): ~150 kilograms (331 lb)

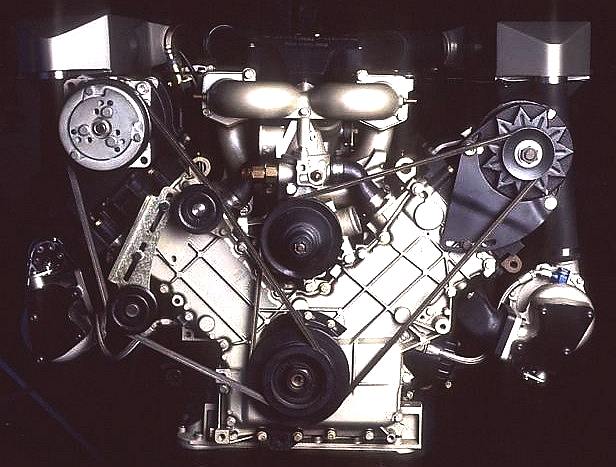

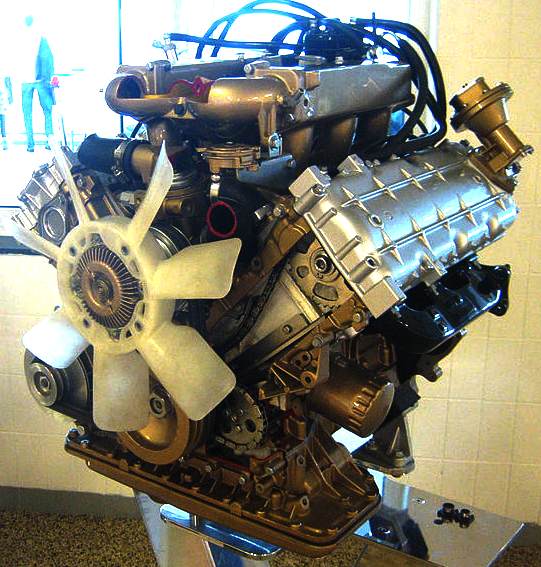

The

Borzoi's engine - PRV V6 as fitted in the Citroen XM

OTHER

VEHICLES USING THE PRV

The dates following each entry denote the introduction of a PRV V6-equipped model

Alpine A310 (October 1976)

Alpine A610 (1991)

Alpine GT/GTA (1984)

Citroën XM (1989)

DeLorean DMC-12 (1981–1983)

Dodge Monaco (1990–1992)

Eagle Premier (1988–1992)

Helem V6

Lancia Thema (1984-1992)

Peugeot 504 coupé/cabriolet (1974/1975)

Peugeot 505 (July 1986)

Peugeot 604 (March 1975)

Peugeot 605 (1990)

Renault 25 (1984)

Renault 30 (March 1975)

Renault Espace

Renault Laguna

Renault Safrane

Talbot Tagora (1980)

UMM Alter II (90's)

Venturi (all models)

Volvo 242GLT/6/244GLT/6/245GLT/6c/262/262C/264/265 (October 1974)

Volvo 760 GLE (February 1982)

Volvo 780 (1985)

Volvo 960 (rare 1991 models)

PRV

ENGINES IN RACING

Alpine A310 V

Fouquet buggies

Peugeot 504 V6 Coupé

Schlesser Original

Venturi 400GTR and 600LM

UMM Alter II

WM Peugeot

The PRV was also the basis for the 90° V6 engine used by Alfa Romeo in the 155 V6 Ti in the 1996 DTM/ITC season from Silverstone onwards. The engines in that series required the use of bank separation angle and cylinder bore spacing from a production based engine, and as a 90° V6 has more room between banks than a 60° V6 for a more optimal induction system,

Alfa Romeo used the PRV as a basis as it had been used in the Lancia Thema, a car which shared it's platform with the Alfa Romeo 164, as well as the Fiat Croma and Saab 900.

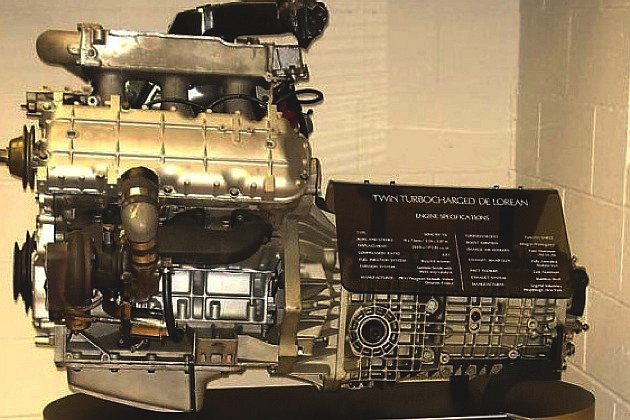

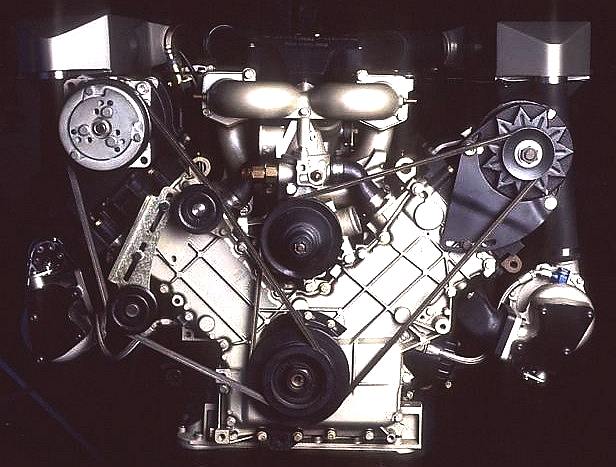

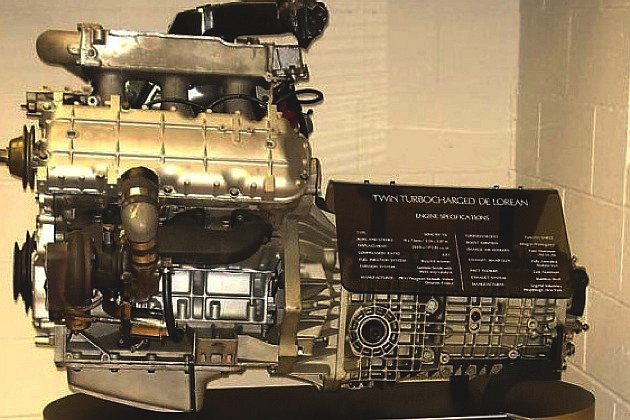

PRV V6 2.8 liter

engine & gearbox as fitted to the DeLorean

Weighing

in at 1,600lbs, the 0-60 time was impressive at around 4 seconds.

A top speed of 170mph was limited by the final drive ratio.

A Renault electronic three speed automatic gearbox was eventually

fitted, mated to a more sedate 2.5 litre unit.

See

the Car development build stages and features below:

Borzoi

Chassis | Borzoi

Bodywork | Borzoi

Joystick | Borzoi

Styling | Borzoi

Engine

CHASSIS |

LOADING-SERVO |

CARTRIDGE | MOTORS |

INSTRUMENTS |

WIND-TUNNEL

The Blueplanet Ecostar is long and low. It features instant battery cartridge

refueling.

The Blueplanet Ecostar is long and low. It features instant battery cartridge

refueling.

The

driver sits at the rear dragster fashion, the battery cartridge is in the

front

all

the way to the nose cone. This is a 500 horsepower car.

Contact us:

Contact us:  or phone UK:

or phone UK:

Intelligent Battery Support System

Intelligent Battery Support System

THE

BLUE BIRDS OF HAPPINESS

|

If

your land speed record car cannot refuel itself, you are

at a huge disadvantage. Blueplanet is around 66% the weight of a

car that does not have cartridge exchange refueling for the same

motor performance.

Blueplanet

has inbuilt battery loaders. It does not need a

Blueplanet

has inbuilt battery loaders. It does not need a

complicated

service station to refuel itself in under 2 minutes. |

The

world's fastest electric circuit racers need a system to recharge

batteries instantly during pit stops. The Formula E concept design above

incorporates the patent Bluebird™ instant energy transfer system -

allowing EV refuelling in around 10 seconds. Get your free developer

License from Bluebird Marine Systems Ltd.

|