|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

HOME | INDEX | AUTOMOTIVE | BLUE PLANET BE3 | ELECTRIC CARS | ENERGY | FORMULA E | NEWS | SOLAR CARS |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

The compound curves of Blueplanet Ecostar, dictate either a hand rolled aluminum construction or a composite moulding. Aluminum fabrication is a highly skilled technique requiring expensive rollers to produce the curves in sections, which are then welded together. The end result is a beautiful classic body, which is likely to be heavier and weaker than its composite counterpart.

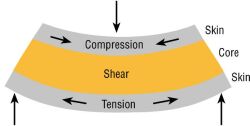

Engineering theory shows that the flexural stiffness of any panel is proportional to the cube of its thickness. The purpose of a core in a composite laminate is therefore to increase the laminate's stiffness by effectively 'thickening' it with a low-density core material. This can provide a dramatic increase in stiffness for very little additional weight.

The figure below shows a cored laminate under a bending load. Here, the sandwich laminate can be likened to an I-beam, in which the laminate skins act as the I-beam flange, and the core materials act as the beam's shear web. In this mode of loading it can be seen that the upper skin is put into compression, the lower skin into tension and the core into shear. It therefore follows that one of the most important properties of a core is its shear strength and stiffness.

In addition, particularly when using lightweight, thin laminate skins, the core must be capable of taking a compressive loading without premature failure. This helps to prevent the thin skins from wrinkling, and failing in a buckling mode.

Overview

PVC Foam

Closed-cell polyvinyl chloride (PVC) foams are one of the most commonly used core materials for the construction of high performance sandwich structures. Although strictly they are a chemical hybrid of PVC and polyurethane, they tend to be referred to simply as 'PVC foams'.

Polystyrene Foams

Although polystyrene foams are used extensively in sail and surf board manufacture, where their light weight (40kg/m3), low cost and easy to sand characteristics are of prime importance, they are rarely employed in high performance component construction because of their low mechanical properties. They cannot be used in conjunction with polyester resin systems because they will be dissolved by the styrene present in the resin.

PMI (Polymethacrylimide) Foams

For a given density, PMI (polymethacrylimide) foams such as ROHACELL® offer some of the highest overall strengths and stiffnesses of foam cores. Their characteristics also include high dimensional stability, a closed cell structure and high fatigue life, and they can be cured and used at elevated temperatures. Their overall cost and performance characteristics mean that, to date, their use has mainly been in higher performance composite parts such as helicopter rotor blades, ailerons and stringer profiles in pressure bulkheads.

Styrene acrylonitrile (SAN) co-polymer Foams

SAN foams behave in a similar way to toughened cross-linked PVC foams. They have most of the static properties of cross-linked PVC cores, yet have much higher elongations and toughness. They are therefore able to absorb higher impact levels.

SAN foams are replacing linear PVC foams in many applications since they have much of the linear PVC's toughness and elongation, yet have a higher temperature performance and better static properties. However, they are still thermo-formable, which helps in the manufacture of curved parts. Heat-stabilised grades of SAN foams can also be more simply used with low-temperature curing prepregs, since they do not have the interfering chemistry inherent in the PVC's. Typical SAN products include ATC Core-Cell's A-series foams.

Core-Cell is the first structural foam designed specifically for the marine industry. In the context of our project, the properties apply equally to vehicle body production.

Not only does Core-Cell offer better handling and machining characteristics, it surpasses all previous limits of stiffness, impact strength and heat distortion temperature. Core-Cell does not out-gas and is compatible with all resin types.

Being closed cell, Core-Cell adds safety, comfort and reassurance to ocean going passages and reduces condensation through insulation. Core-Cell is preferred by professional builders and has an excellent reputation with amateurs for being easy to form around tight curves, but stiff enough to strip plank between temporary frames.

For in-mould applications Core-Cell reduces resin usage and weight by its unique double-cut and triple-cut sheets. The invisible knife cuts open less than other contourable foams when curved meaning less chance for voids and/or delamination.

The Blueplanet Ecostar - composite bodywork

The driver sits at the rear dragster fashion, the battery cartridge is in the front all the way to the nose cone. Check out the battery cartridge exchange sequence below.

+44 (0) 1323 831727 +44 (0) 7842 607865 Bluebird Marine Systems Ltd

THE BLUE BIRDS OF HAPPINESS

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

EDUCATION | E. CYCLES | SOLAR CARS | SOLAR CAR TEAMS | SOLARNAVIGATOR |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

This

website is copyright © 1991- 2013 Electrick Publications. All rights

reserved. The bird logo Max Energy Limited is an educational charity working for world peace. |

|||||||||||||||||||||||||||||||||||||||||||||||||||

The Blueplanet Ecostar is long and low. It features battery cartridge

refueling.

The Blueplanet Ecostar is long and low. It features battery cartridge

refueling.

Contact us:

Contact us:

Intelligent Battery Support System

Intelligent Battery Support System