|

FCH2020-3 LIQUID HYDROGEN

AUTOMOTIVE A TO Z CLIMATE CHANGE A TO Z CONTACTS EVENTS GROWTH A-Z PLEASE USE OUR SITE INDEX TO NAVIGATE THIS SITE |

|

|

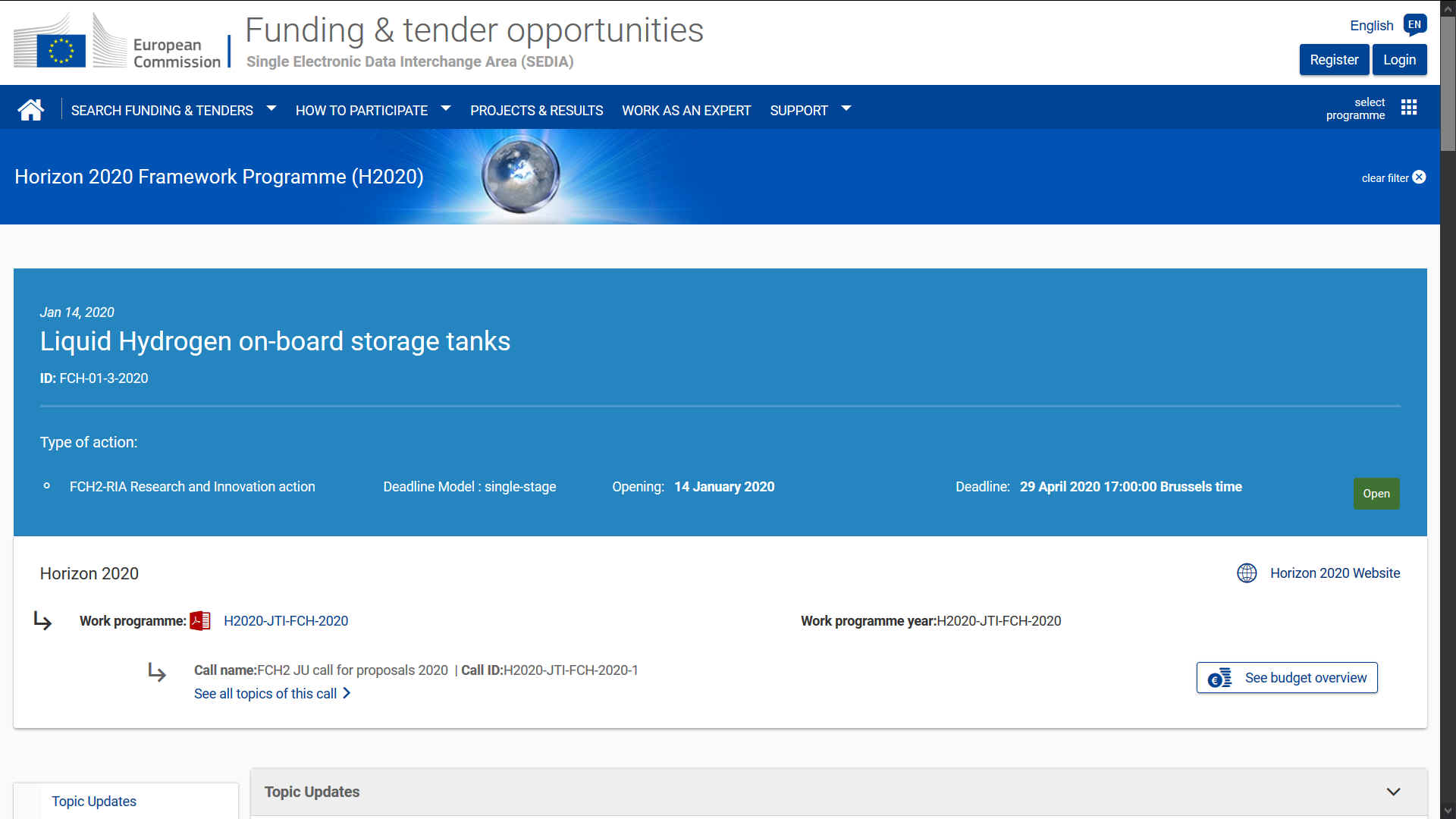

H2020-JTI-FCH-2020-1

: FCH-01-3-2020

Liquid Hydrogen on-board storage tanks

The range limitation is less critical for fleet trucks with short routes: 350 bar H2 storage seems to be sufficient for municipal vehicles, buses and even parcel delivery trucks. For trucking applications with larger payload and less dense HRS network, for instance regional and long haul, other solutions need to be investigated.

Pressures

of 500 to 700 bar indeed offer more volumetric capacity (more than 20 to

45% over 350 bar) but these solutions are costly and bring in hurdles on

the infrastructure where large capacities need to be dispensed rapidly,

while controlling the inlet temperature and allowing high station demand

(“back-to-back”).

* For reference, estimated performances for the BMW 7 LH2 storage system are 9% wtH2 and 40 gH2/L for a capacity of 8 kg H2

BATTERY CARTRIDGE FORMAT PROPOSAL - This cartridge format provides 0.24 of a meter cubic capacity. All of these formats can be used in multiples to provide up to 1.92 of a cubic meter capacity. This is one of a number of sizes that we will be evaluating as part of a study we hope to obtain funding for - to define a universal format or international standard.

AUTOMOTIVE EV COMPARISON - Where charging up a battery-powered car can take anything from half an hour to a whole night, you can refuel a hydrogen car in just five minutes using flexible hoses. But, you can also refuel a battery car in less time using cartridge exchange. Meaning that hydrogen loses out, if we take into account conversion losses. For this reason hydrogen is unlikely to achieve the same level of market penetration, without a means to work alongside battery vehicles, such that the choice for the buying public is not such a risk, as if putting all their eggs in one basket.

Scope:

A few configurations will be used as benchmark: rail mounting, behind cab, and within frame. The overall shape of the storage system is important, and advanced storage solutions to optimize the energy density (through e.g. a single vacuum jacket with multiple cylinders) should be investigated.

The

mechanical design should meet all requirements typical of the trucking

industry in terms of durability, exposure to harsh environments,

vibrations, accelerations, safeties. Pressure in the LH2 storage tank

should be compatible with the pressure at which the fuel

cell typically operates. Alternatively,

mitigation strategies should be proposed.

TRL

at start of the project: 4

and TRL at the end of the project: 5.

Expected

Impact:

- Volumetric capacity at tank system level: 0.045kg/L28;

-

Gravimetric capacity at tank system level: 10% (H2/(H2+tank system)).

THE SLOW LANE - We all live fast lifestyles. Waiting 30 minutes for rapid charging not only strains the grid, but also damages batteries, and nobody has thirty minutes to waste - best case - worst case 6-8 hours. A truck size battery would take hours to (so-called) rapid charge. It is just not practical. Ignoring for now that there are no charging points along the streets in towns and cities, or at supermarkets. Even faster charging is envisaged, with catastrophic consequences for the National Grid without load levelling.

1:20 SCALE MODEL - April 6 2020, a model of a service station that can refuel buses, truck and cars is under construction in workshops in Sussex, England. Seen here are two 1:20 scale Mercedes articulated container trucks inside. The makers are using plywood for the model of the building and some of the working parts - that cannot be shown due to patent law prohibiting prior publication. The Automated & Electric Vehicle Act 2018, makes it law in England that provision must be made for charging and refuelling of electric vehicles at service stops. This system would more accurately be described as a refuelling point - since the energy exchanges for trucks and cars are virtually instant. The full size building can be a quarter this size for city locations where space is limited. But for load levelling purposes, the larger the capacity of stored electricity, the more efficient the grid. Copyright photograph © 6 April 2020, Cleaner Ocean Foundation.

SMART-CHARGER - Potentially the world's fastest electric car: 400mph using energy from nature. Featuring built in energy cartridge swapping system, charged using renewable solar energy. A project in waiting in PR terms to celebrate the banning of petrol and diesel cars in Europe and the UK from 2030.

|

|

|

The

content of this website is copyright © 2020 Electrick

Publications. All rights reserved. The bluebird logo

|